In 1958, the Cabinet of Ministers of the USSR passed a decision on the construction of the Olaine Chemical Reagent Factory. The Cabinet of Ministers of the Latvian SSR determined the construction of the factory in the period from 1963 to 1965.

In 1958, the Cabinet of Ministers of the USSR passed a decision on the construction of the Olaine Chemical Reagent Factory. The Cabinet of Ministers of the Latvian SSR determined the construction of the factory in the period from 1963 to 1965.

1963

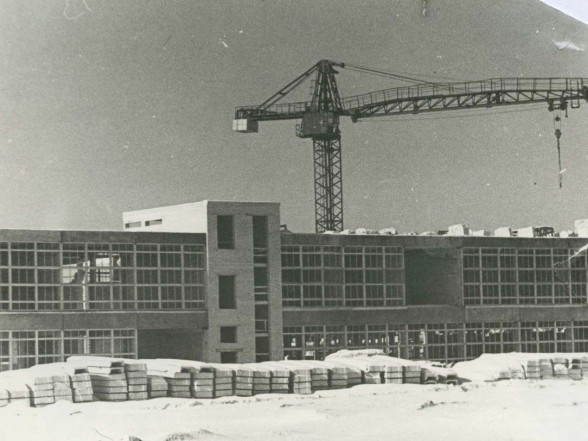

In 1963, together with the construction of the Olaine Plastics Processing Factory, the construction of the central laboratory building of the Olaine Chemical Reagent Factory was started. The factory project was created by "Giprohimreaktiv" from Kharkov. Graduates of the 35th Vocational Technical School and prisoners who worked under the supervision of construction specialists participated in the construction works. According to the project, the building of the central laboratory was intended as a four-story building with specially built laboratory rooms. Before the commissioning of the central laboratory building, the director of the factory was J. Staivo.

1965

In 1965, the building of the central laboratory was put into operation. G. Gaišais became the director of the factory. After the completion of the construction works, the students of the 35th Vocational Technical School arranged, washed and cleaned the premises of the factory’s central laboratory for days.

1966

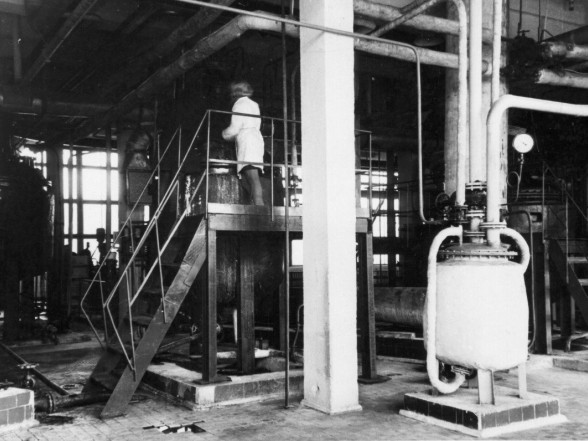

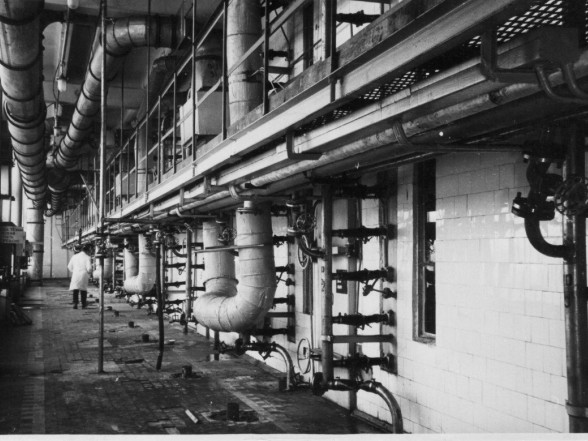

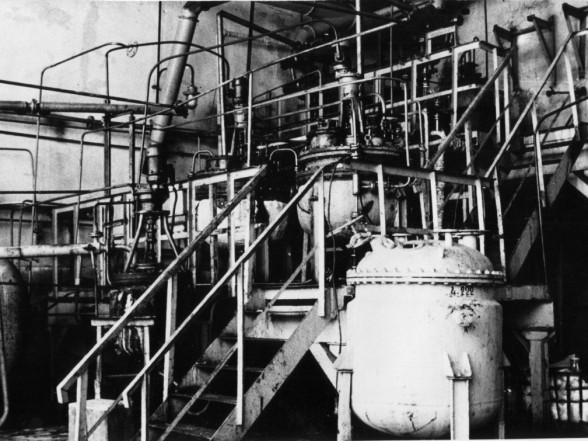

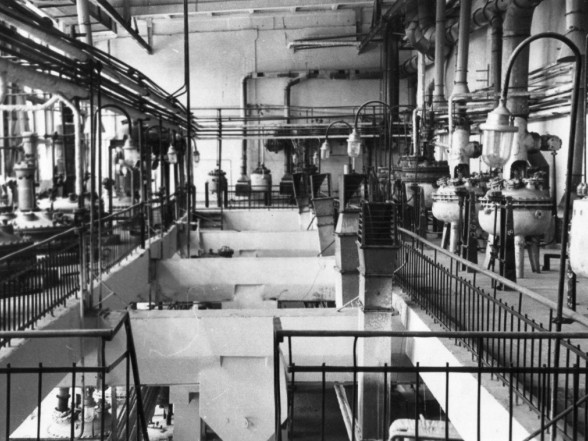

In 1966, the Olaine Chemical Reagent Factory commenced production. Boriss Ļebedevs, the former director of the Riga Cement Factory, became the director of the factory. The central laboratory of the plant put the first development into production in 1966, and by 1971 it had developed almost 500 preparations. On July 10, 1966, the plant’s itaconic acid workshop was put into operation. Itaconic acid was used in the production of synthetic detergents, and the one produced in Olaine was cheaper and of better quality.

1968

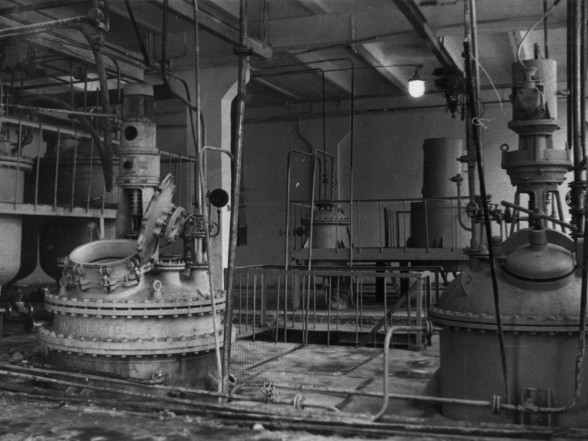

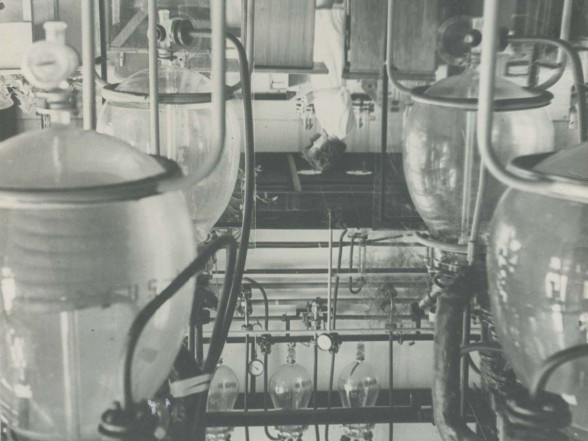

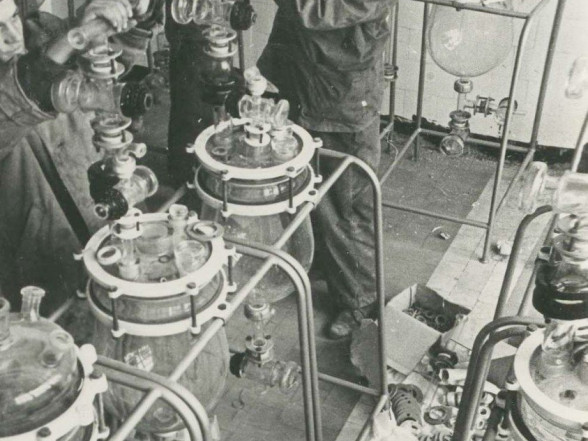

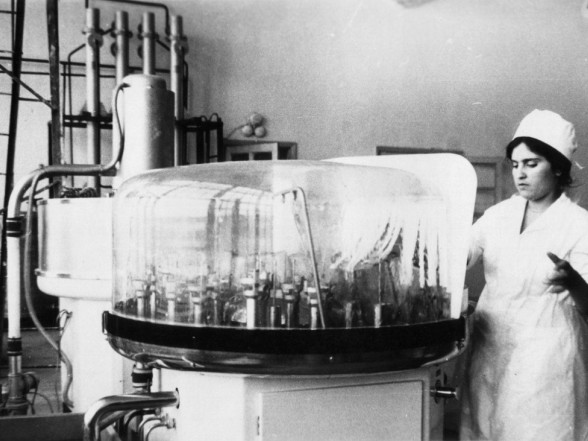

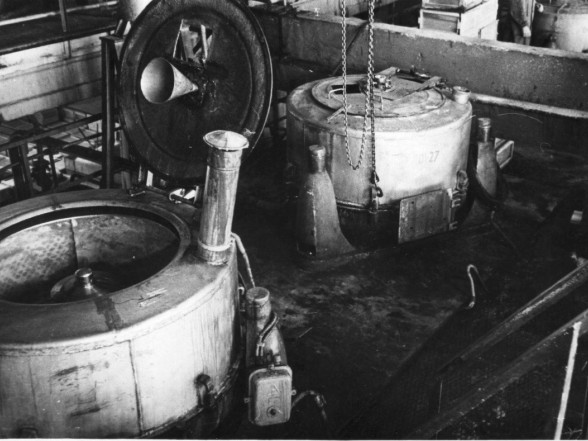

In 1968, a workshop for biochemical preparations was put into operation, producing enzymes, proteins and other biochemical preparations for the food industry, medicine and the needs of microbiologists.

1972

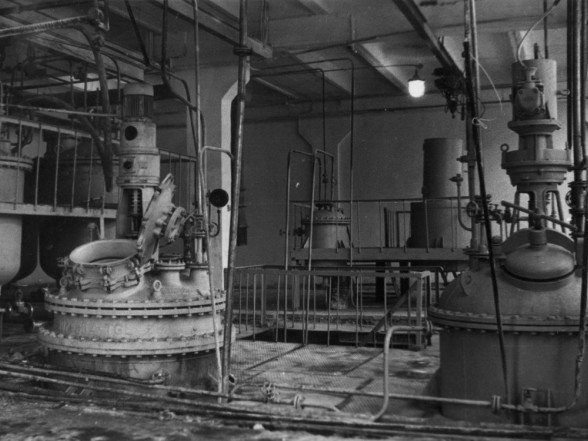

In 1972, the last large production building of the factory – the organic synthesis workshop – was put into operation. This workshop produced preparations of organic synthesis, which were used in research, medical industry, economy and agriculture.

The total area of the factory covered 17.2 ha, and apart from the production workshops, the factory had its own water treatment facilities, a block of auxiliary workshops, a nitrogen and oxygen station. A room with a peculiar name – “Vivarium" – was built next to the biochemical preparations production plant. The vivarium building was meant for keeping animals for scientific research, but since the factory did not conduct research with animals, dormitories for the factory’s engineering staff and workers were installed in the vivarium.

Creation of the Association "Biochemical Reagents"

In 1976, by order of the Ministry of Chemical Industry of the Union of Soviet Socialist Republics, the Scientific Production Association "Biochemical Reagents" was established. The association included: All-Union Scientific Research Institute of Practical Biochemistry "IREA", Olaine Chemical Reagent Factory and Factory No. 1 plant "Reagent". V. Zamahs was appointed as the general director of the association.

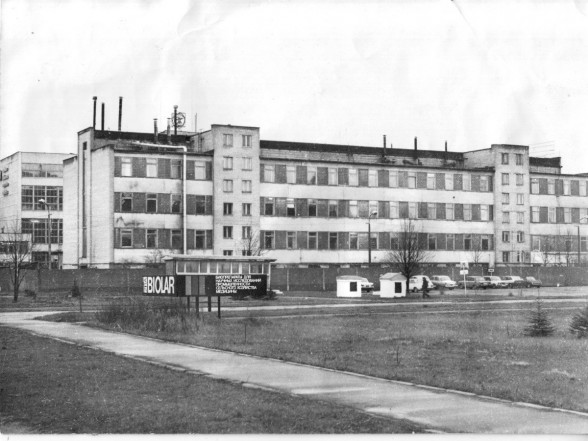

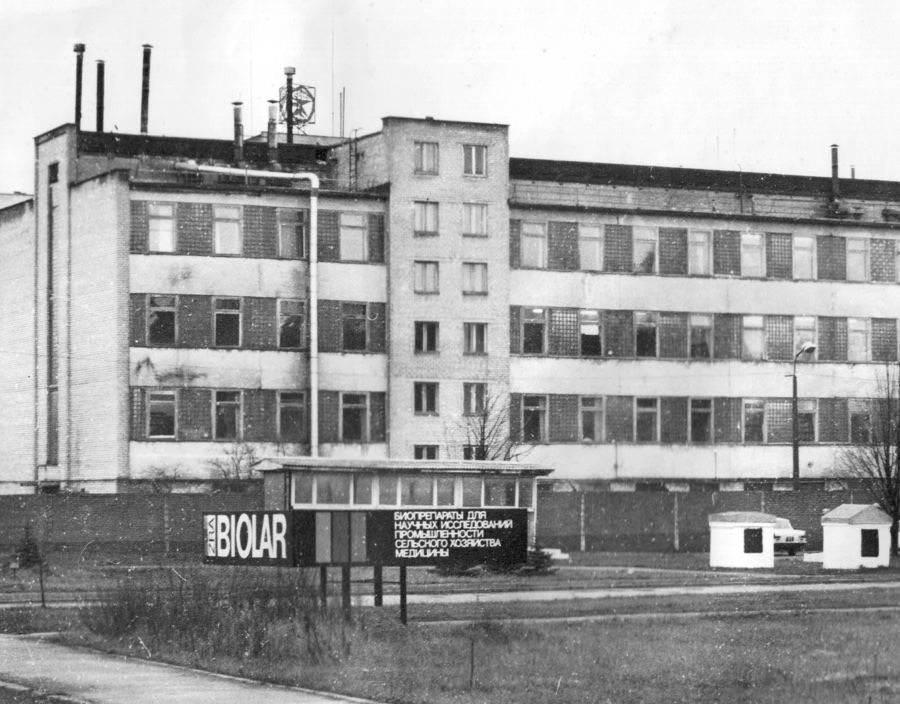

The Olaine Chemical Reagents Factory was the experimental base of the association, where new technologies for the creation of chemical reagents and biochemical preparations and for the industrial production of previously imported chemical reagents and biochemical preparations were practically learned and perfected. In 1985, the Scientific Production Association "Biochemical Reagents" changed its name to the Scientific Production Association "Biolar", or ZRA "Biolar".

The factory’s main occupation, achievements, scientific discoveries

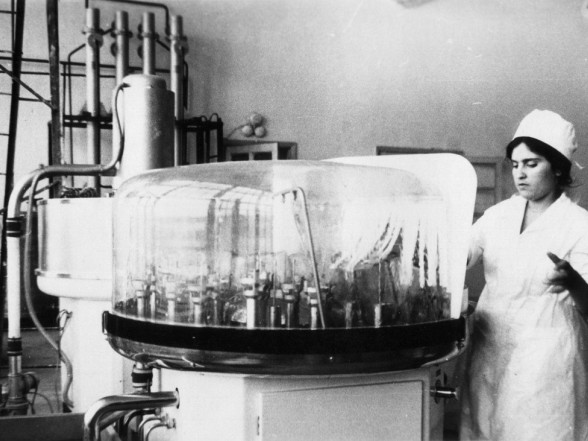

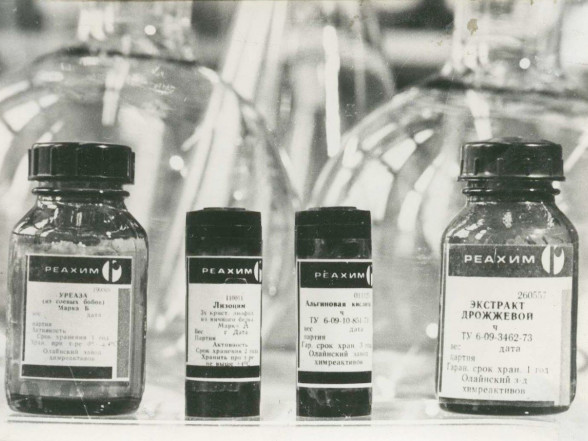

The basic function of the Olaine Chemical Reagents Factory was to develop and put into production new chemical reagents and biochemical, organic synthesis preparations for the needs of scientific research work, food industry, medical industry and agriculture. The assortment produced by the factory also included secret products for military and space research needs, for example, in the first-aid kits of Soviet cosmonauts, there was "Phenibut" produced by "Biochemical Reagents".

Science

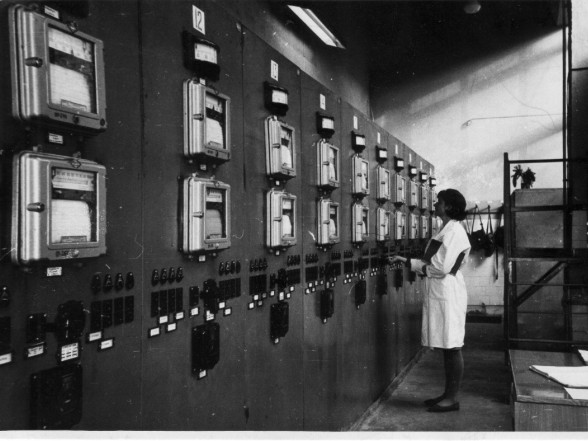

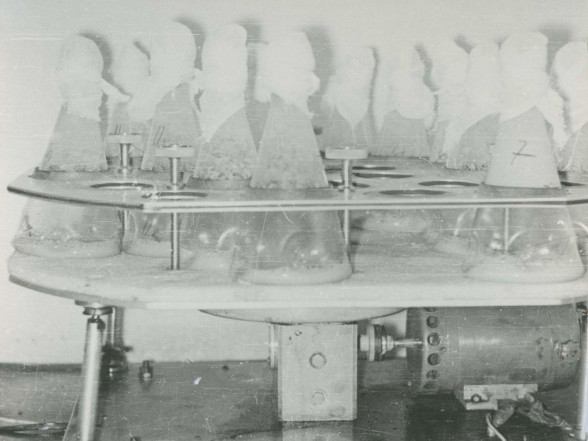

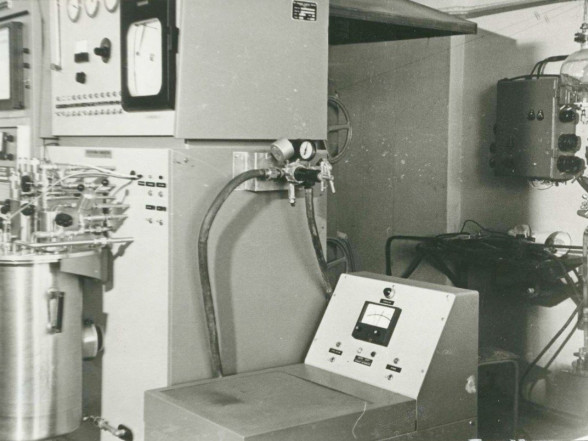

The factory regularly cooperated in the field of scientific research with scientific research institutes in Moscow, Leningrad and Riga in order to improve research work and obtain better results. The factory, unlike the other Olaine plants, not only produced, but also contributed greatly to the field of chemistry, molecular biology and genetic engineering. The factory also produced chemical preparations for the destruction of weeds in fields, which was a product in demand in collective farms and Soviet farms. Many scientists and scientific workers who worked on research were graduates of Olaines 35th Vocational Technical School and many other universities and technical schools. Methods of obtaining chemical compounds were already studied before the factory workshops and the laboratory were put into operation.

On August 31, 1962, the Specialised Bureau of Designers was established for the development of the industrial production method of piperazine. In 1970, a patent department for scientific – technical and economic information was established in the factory, and Uldis Kauliņš was appointed as its head. The task of the department was the identification of new preparations, the search for methods of acquisition and the preparation of informative materials. The department organised scientific conferences, meetings and other events. The department had a wide library of scientific literature, the task of which was to supply engineers and technical workers with scientific and technical literature. In 1985, the library had 10 000 items of scientific literature. The scientific workers of the factory were from all over the Soviet Union. Some of the employees had graduated from universities of the Latvian SSR – UL, LUA, RPI (Riga Polytechnic Institute).

In the early eighties, in the itaconic acid workshop research was conducted to replace sugar with a cheaper material, but the research was not completed, because in 1990 the production of itaconic acid was discontinued. The central laboratory of the factory was equipped with the most modern foreign equipment and facilities for analysis and research. In the research work, the factory also cooperated with other institutes and organisations that worked on the basis of contracts for the needs of the scientific research of the factory. Such outsourcing had a big disadvantage – “leakage of production secrets”. The production of Phenibut can be mentioned as one of the precedents. In this regard, the Supreme Council of the USSR was involved, which helped to strengthen the copyright of this substance. A patent and rationalisation working group was created at the factory, which was later transformed into a department. The department successfully protected the intellectual property rights of the factory, and by 1990 the factory had received 512 patents for the products it created. Scientific employees of the plant wrote scientific publications in newspapers, scientific magazines, and created conference materials. By 1990, 1 220 scientific works had been published.

Production

In addition to research, the factory also increased production volumes. In 1979, the organic synthesis workshop produced production in the amount of 10.3 million roubles. In 1979, the profit of the products produced at the Biochemical Preparations Workshop was 6.6 million roubles. The amounts of raw materials used in production are enormous. Mainly food products are used. In the period from 1966 to 1978 44.6 tons of bread yeast, 2 million eggs, 30 tons of pig blood, 4.5 tons of animal kidneys and sugar were used in production.

In 1988, the factory’s production rates dropped sharply. In 1988, ZRA "Biolar" production rates were reduced to 75 tons. In 1991, the range of manufactured products decreased rapidly. In 1992, ZRA "Biolar" became the Latvian state company "Biolar".

Further development of the factory

In 1992, the scientific production association "Biolar" became a state company under the name "Biolar". As a result of the changes, the scientific staff lost the most jobs. No research and scientific discoveries were made.

The plant had become a centre of Applied Biochemistry. The factory had reduced its production capacity to a minimum, as a result of which the factory had no income and funds to pay for the employees and the consumed electricity. In July 1992, the total debt of the factory for consumed electricity and transport services reached 16 million roubles. In 1994, "Biolar" ceased to exist as a state company.

In 1995, a new company LLC "Latbio" was established on the basis of ZRA "Biolar".

Jurijs Daņilko became the general director of the company, who with his experience and knowledge changed the assortment of the factory’s products, invested funds in scientific research and increased production volumes. The company engaged in experimental developments in the field of chemistry and the production of technologically complex chemical products. The production was exported mainly to Russia, Belarus, Ukraine and the Baltic States. The factory also financially supported the Latvian hockey team and the Latvian football team.

1996 – The production capacity of the production company LLC "Nitra" (founded in 1987) was transferred to the territory of the factory. A workshop for the production of metal containers for the needs of the paint and varnish production plant was also put into operation.

The production of siccatives (an additive for accelerating the drying of paints and varnishes) was started. The first production plant of mixed siccatives in the post-Soviet territory.

An acrylic resin production plant was put into operation.

Azo-initiator - AIBN production plant was put into operation.

A new alkyd resin production workshop was commissioned.

Production of plasticisers started.

1999 – An agreement was signed between LLC "Latbio" and the Latvian Privatisation State Agency for the purchase and privatisation of the "Biolar" factory.

In 2002, the factory was privatised and in the same year, the production of chemicals in LLC "Latbio" and the production of lacquers and paints in LLC "Nitra" were merged into one company.

After privatisation, the name of the factory was changed from LLC "Latbio" to LLC "Olaines ķīmiskā rūpnīca BIOLARS". Jurijs Daņilko became the head of the new company.

The production of canning varnishes (for processing canning containers) is commenced.

The production of acetonitrile with a high degree of purification for the pharmaceutical industry is launched.

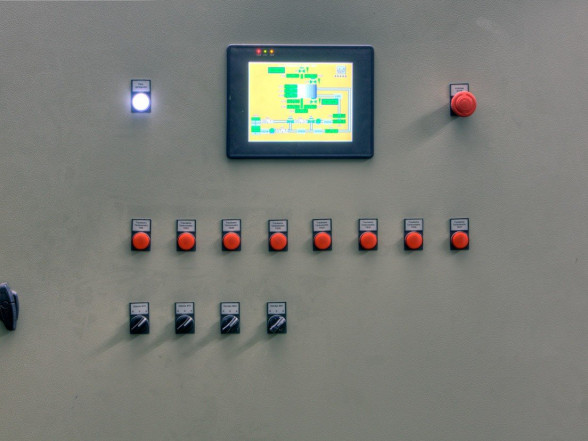

New, fully automatic production lines for the production of Azo-initiator – AIBN were put into operation, increasing production output.

A new facility for the production of Azo-initiator – AIVN was put into operation.

2017 – Modernised and put into operation, a new modern treatment plant for biological wastewater treatment.

2017 – The limited liability company "Olaines Ķīmiskā rūpnīca BIOLAR" was transformed into a joint-stock company – JSC "Olaines Ķīmiskā rūpnīca BIOLAR".

2022-2025. Modernisation of wastewater biological treatment facilities and their commissioning are planned. It is planned to put into operation the new fully automatic Azo-initiator – AIVN production line, increasing the production volume. It is planned to put into operation the new Azo-initiator production plant – ADVN.

Olaine chemical factory "BIOLARS" today is a company with efficient equipment, high production culture and technical-economic indicators. The basis of the company’s policy is the provision of Latvian and foreign markets with high-quality products developed in accordance with the best traditions of the Latvian school of chemistry, nowadays needs and consumer requirements.

Today, the company specialises in experimental developments in the field of chemistry, production of technologically complex chemical products, semi-finished products of the varnish and paint industry, as well as producing finished varnish and paint products. The company also produces construction, automotive and household chemicals. The company has several laboratories that were engaged in the scientific research of chemical products and processes.

Entering the market economy, applying the new management methods, the company was looking for ways to restore broken vertical and horizontal connections.

Modern technologies and the professionalism of employees, a powerful production base, as well as a developed infrastructure of the company (railway access road, warehouse facilities, the possibility of unloading, loading and processing cargo), the proximity of a port with chemical terminals, an advantageous geographical location in the East-West direction are a good basis for increasing production volumes and for a successful, mutually beneficial partnership.